The Future of Automation in Manufacturing | Machines vs. Human Labor

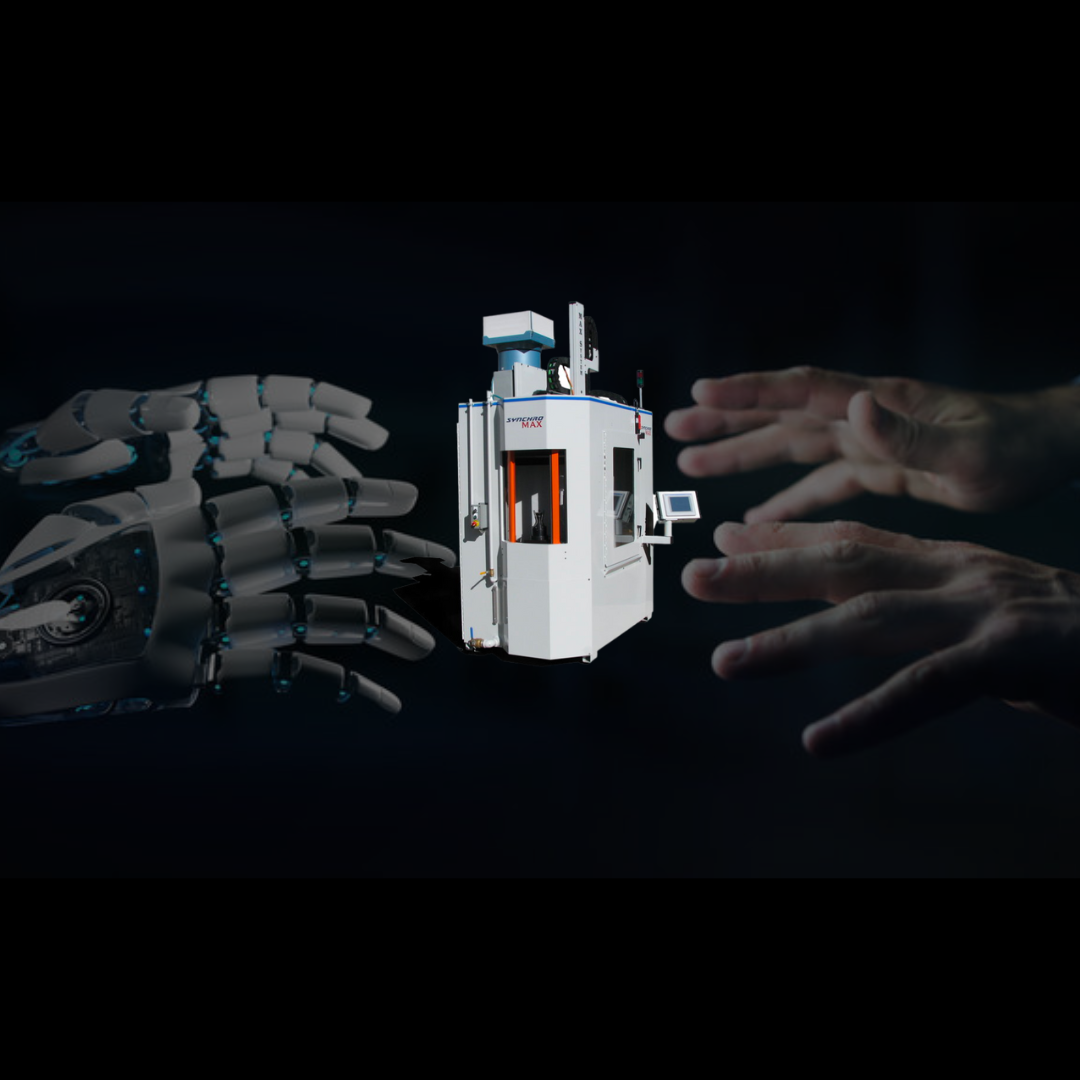

As manufacturing landscapes evolve, automation emerges as a crucial solution for optimizing processes like deburring and chamfering. This article explores the pressing need for automation in manufacturing, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

Automation in Part Manufacturing

As manufacturing landscapes evolve, automated deburring emerges as a crucial solution for optimizing processes like machine deburring and machine chamfering. This blog explores the pressing need for automated deburring, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

The Need for Automated Deburring in Part Finishing

Modern manufacturing demands high levels of efficiency and precision, especially in tasks like deburring and chamfering critical for part quality. Human labor, while skilled, faces challenges such as fatigue, variability, and safety risks. These factors hinder consistent production output and quality assurance, necessitating a shift towards automation.

Challenges of Human Labor

Limitations and Safety Concerns

Manual hand deburring and chamfering tasks are time-consuming and physically demanding, leading to potential errors and variability in results. Moreover, human operators face safety risks associated with handling sharp edges and heavy machinery, impacting both productivity and worker well-being.

Challenges of Industrial Robots

Rigidity and Adaptability

Traditional industrial robots, while efficient in certain tasks, often lack the adaptability required for complex deburring and chamfering processes. Their rigid programming limits flexibility, leading to challenges in handling diverse workpiece geometries and achieving consistent results across different parts.

Focused Deburring

Precision and Adaptability in Automated Deburring

James Engineering experts emphasize the significance of compliant technology in addressing these challenges. Their patented Focused Deburring can adapt to varying workpiece geometries, ensuring precise and consistent results without constant manual adjustments, or the need to mask parts. This adaptability reduces errors, enhances quality control, and streamlines manufacturing processes. Ensuring the next level of precision in deburring machines.

Integrating Automation for Sustainable Manufacturing

The evolution of manufacturing hinges on integrating automation solutions that combine efficiency, precision, and safety. By addressing the limitations of human labor and traditional robotic systems, manufacturers can achieve higher productivity, quality assurance, and workforce empowerment. Experts like James Engineering offer valuable insights and solutions that pave the way for a sustainable and innovative manufacturing future.

See the different system options here.

Contact us to determine which system best suits your manufacturing needs.

Deburring for Different Industries: Custom Solutions for Unique Needs

Different industries have unique deburring requirements based on the materials they work with, the specific applications of their products, and the desired quality standards. As such, custom deburring solutions tailored to each industry's needs are essential for achieving optimal results. Let's explore how deburring is applied in various industries and the importance of custom solutions.

Deburring is a critical process in manufacturing that involves the removal of burrs, sharp edges, and other imperfections from metal, plastic, wood, and other materials. These imperfections can arise during machining, casting, forging, or other fabrication processes. Deburring not only enhances the aesthetics of the final product but also ensures safety and functionality by eliminating potential hazards and improving surface quality.

Different industries have unique deburring requirements based on the materials they work with, the specific applications of their products, and the desired quality standards. As such, custom deburring solutions tailored to each industry's needs are essential for achieving optimal results. Let's explore how deburring is applied in various industries and the importance of custom solutions.

The importance of precise chamfer lies in its ability to enhance the structural integrity and aesthetic appeal of engineered components, ensuring seamless assembly and optimal functionality in various applications.

Automotive Industry

Automotive Industry has varied components such as engine parts, transmission components, chassis components, and body panels that require deburring or chamfering

In the automotive industry, deburring plays a crucial role in ensuring the quality and performance of components such as engine parts, transmission components, chassis components, and body panels. Burrs left on these parts can interfere with proper assembly, cause premature wear, and compromise safety.

Custom deburring solutions for the automotive industry often involve automated processes such as multi axis systems equipped with specialized tools for consistent and efficient burr removal. Additionally, industry-specific chamfer or radius techniques, for complex-shaped parts or bulk processing of small components, are employed to meet the industry's stringent quality standards.

Deburring complex aerostructure parts poses unique challenges due to their intricate designs and critical role in aerospace applications. Our advanced solutions address these complexities, ensuring thorough and precise deburring for enhanced performance and safety in aircraft manufacturing.

Aerospace Industry

The aerospace industry demands the highest precision and reliability in its components to ensure the safety of aircraft and spacecraft. Deburring is critical in aerospace manufacturing to eliminate any surface imperfections that could compromise aerodynamics, structural integrity, or functionality.

Custom deburring solutions for the aerospace industry often incorporate advanced Focused Deburring technologies for intricate and delicate parts like turbine blades, airfoils, and engine components. These techniques enable precise edge and surface finishing without compromising the dimensional accuracy or material properties of the parts.

Medical device finishing plays a crucial role in ensuring the safety, functionality, and regulatory compliance of medical equipment, encompassing processes such as polishing, washing, deburring, and radius machining.

Medical Device Manufacturing

In the medical device manufacturing industry, where precision, cleanliness, and biocompatibility are paramount, deburring plays a vital role in ensuring the safety and effectiveness of medical implants, surgical instruments, and diagnostic equipment.

Custom deburring solutions for medical device manufacturing often involve specialized 11 axis and multiple tools to achieve smooth, clean surfaces free of burrs and contaminants.

Delving into micron-level deburring is pivotal in both medical device manufacturing and aerospace engineering. This precision process guarantees smooth surfaces and optimal functionality in medical parts, while also enhancing the performance and reliability of intricate aerospace components for seamless operation in challenging environments.

Micron Industry

In precision-focused industries, deburring is crucial for ensuring the functionality and reliability of components requiring micron-level precision. Custom deburring solutions often employ precise techniques and specialized equipment with programmable controls to meet exacting standards for product quality and performance.

Deburring is an essential process in manufacturing, serving diverse industries including automotive, aerospace, medical devices, electronics, and more. Customized deburring solutions tailored to each industry's needs are crucial for achieving top-quality results.

By investing in industry-specific deburring solutions, manufacturers ensure product integrity, reliability, and safety while meeting industry standards.

To learn how automated deburring and chamfering can work for your industry, contact The Deburring Experts at Sales@James-Engineering.com

Maximizing Efficiency: How Automated Deburring Systems Revolutionize Manufacturing

In the fast-paced world of modern manufacturing, the quest for efficiency is relentless. Every step in the production process must be optimized to meet the demands of precision, speed, and cost-effectiveness. One area where significant strides have been made is in the realm of deburring, and the introduction of automated deburring systems has revolutionized the manufacturing landscape. This article delves into the transformative impact of automated deburring, exploring its benefits, applications, and how it has become a cornerstone for maximizing efficiency in diverse industries.

In the fast-paced world of modern manufacturing, the quest for efficiency is relentless. Every step in the production process must be optimized to meet the demands of precision, speed, and cost-effectiveness. One area where significant strides have been made is in the realm of deburring, and the introduction of automated deburring systems has revolutionized the manufacturing landscape. This article delves into the transformative impact of automated deburring, exploring its benefits, applications, and how it has become a cornerstone for maximizing efficiency in diverse industries.

The Evolution of Deburring:

Deburring, once a manual and time-consuming process, has undergone a remarkable evolution with the integration of automation. Traditionally, workers meticulously removed burrs and sharp edges from machined components, a task that was not only labor-intensive but also prone to variations in quality. Automated deburring systems have emerged as a game-changer, offering a streamlined and consistent approach to this crucial manufacturing step.

Benefits of Automated Deburring Systems:

Precision and Consistency:

Automated deburring systems provide unparalleled precision, ensuring that every component is treated with the same level of accuracy. This consistency is vital in industries where even the slightest deviation from specifications can lead to performance issues or product defects.

Time Efficiency:

Time is of the essence in manufacturing, and automated deburring significantly reduces cycle times. The swift and continuous operation of robotic systems allows for a faster throughput of components, contributing to overall production efficiency.

Labor Cost Savings:

The automation of deburring processes translates into reduced labor costs. Manufacturers can reallocate human resources to more intricate tasks, while automated systems handle the repetitive and time-intensive nature of deburring.

Enhanced Safety:

Manual deburring poses risks to workers due to sharp edges and repetitive motion injuries. Automated systems eliminate these safety concerns, creating a safer working environment and reducing the likelihood of workplace accidents.

Applications Across Industries:

Automated deburring systems find applications in a myriad of industries, from aerospace and automotive to electronics and medical device manufacturing. The versatility of these systems allows them to adapt to various materials, geometries, and part sizes, making them an invaluable asset in diverse production environments.

Technological Advancements:

The 11-Axis MAX system has further enhanced the capabilities of automated deburring systems, taking them next level. Intelligent and easy to use, these systems adapt to different materials and geometries, optimizing the deburring process for each unique component.

Case Studies:

Several manufacturing leaders have reported substantial improvements in efficiency, quality, and cost savings after implementing automated deburring systems. Real-world examples showcase how these systems have become a cornerstone of lean manufacturing practices, driving competitiveness in the global market.

The integration of automated deburring systems represents a transformative leap forward in manufacturing efficiency. As industries continue to push the boundaries of innovation, automated deburring emerges as a key player, ensuring that components meet stringent quality standards while optimizing production processes. Manufacturers embracing these advanced systems are not just keeping pace with the demands of the market; they are setting new standards for efficiency and reliability in the modern era of manufacturing.

To learn more about what all the MAX has to offer, email us or call us at (303) 444-6787