What is Gear Hobbing?

Understanding Gear Hobbing and Deburring in Manufacturing. What is Gear Hobbing? Gear hobbing is a machining process used to cut gears, splines, and sprockets. What is the Difference Between Gear Cutting and Hobbing? Why is it Important to Remove Burrs? What is the Effect of Deburring?

We answer ALL your questions!

Understanding Gear Hobbing and Deburring in Manufacturing

In manufacturing, precision and efficiency reign supreme. At the heart of achieving these goals are understanding two pivotal processes: gear hobbing and deburring. This article will explore what gear hobbing is, distinguish it from gear cutting, and delve into the importance of removing burrs and the effects of deburring.

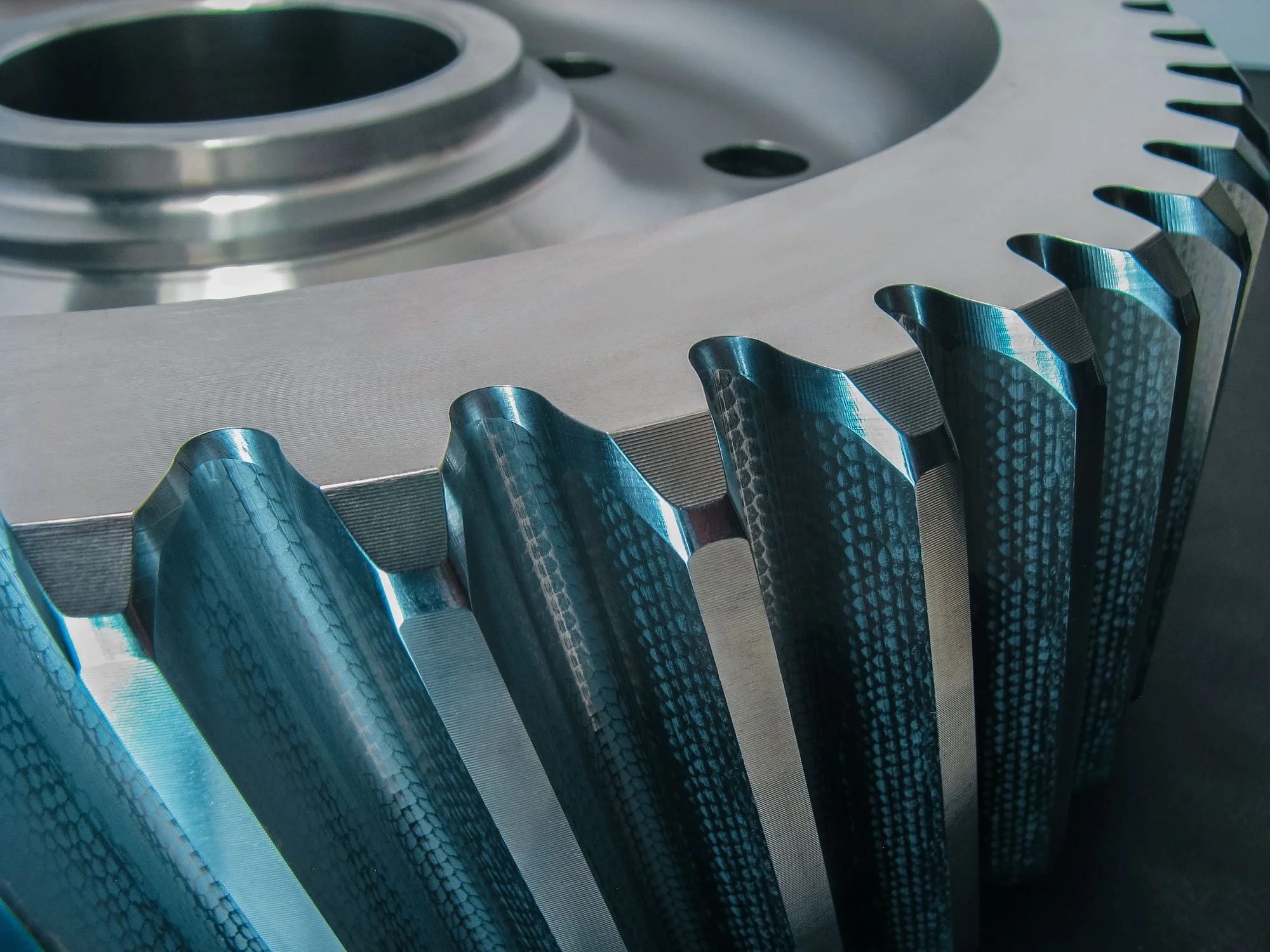

What is Gear Hobbing?

Gear hobbing is a machining process used to cut gears, splines, and sprockets. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. This process is highly efficient and can produce a wide range of gear sizes and shapes with high precision. Gear hobbing is commonly used in the automotive, aerospace, and machinery industries due to its ability to produce high-quality gears at a relatively low cost.

What is the Difference Between Gear Cutting and Hobbing?

While gear hobbing is a type of gear cutting, not all gear cutting processes are hobbing. Gear cutting is a broad term that encompasses various methods used to create gear teeth, including hobbing, shaping, milling, and broaching.

Gear Hobbing: Utilizes a hob and is suitable for producing both spur and helical gears. It is known for its efficiency and versatility in creating various gear profiles.

Gear Shaping: Uses a reciprocating cutter to cut the gear teeth. It is particularly useful for internal gears and gears with complex shapes.

Gear Milling: Involves using a milling machine and a form cutter to create the gear teeth. This method is typically used for small production runs or prototype gears.

Gear Broaching: Uses a toothed tool called a broach to cut the entire gear profile in a single pass. It is ideal for producing large quantities of gears quickly.

Each of these methods has its advantages and specific applications, but gear hobbing is often favored for its combination of speed, precision, and versatility.

Why is it Important to Remove Burrs?

Burrs are unwanted, rough edges or protrusions that remain on metal parts after machining processes such as cutting, drilling, or grinding. These burrs can have several detrimental effects if not removed:

Safety Hazards: Burrs can cause injuries to workers handling the parts.

Assembly Issues: Burrs can interfere with the proper fitting and functioning of parts in assemblies.

Performance Problems: Burrs can affect the performance and longevity of mechanical components, leading to increased wear and tear or even failure.

Aesthetic Concerns: Burrs can negatively impact the appearance of the final product.

Why is Deburring Necessary?

Deburring is the process of removing burrs from metal parts. It is a crucial step in the manufacturing process for several reasons:

Enhances Safety: By removing sharp edges, deburring prevents potential injuries to workers and end-users.

Improves Functionality: Deburred parts fit together more precisely, ensuring proper assembly and optimal performance of mechanical systems.

Extends Product Life: Deburring reduces friction and wear, which can extend the lifespan of components.

Ensures Quality: Removing burrs improves the overall quality and appearance of the product, making it more attractive to customers and less likely to be returned due to defects.

What is the Effect of Deburring?

The effects of deburring extend beyond mere aesthetics and safety. Deburring can significantly impact the overall quality and performance of manufactured parts. Here are some key effects:

Enhanced Durability: By eliminating stress concentrations that can lead to cracks or failures, deburring contributes to the structural integrity of components.

Improved Precision: Deburred parts have cleaner edges and more accurate dimensions, which is critical for applications requiring high precision.

Better Surface Finish: The removal of burrs results in a smoother surface finish, which can improve the part's functionality and reduce the risk of corrosion.

Increased Efficiency: Parts that fit together properly reduce the likelihood of mechanical failures and downtime, leading to more efficient operation of machinery and equipment.

In conclusion, gear hobbing and deburring are essential processes in the manufacturing industry. Gear hobbing allows for the efficient and precise production of gears, while deburring ensures the safety, functionality, and quality of the final products. Understanding these processes and their significance helps manufacturers produce high-quality components that meet the rigorous demands of various industries.

WHAT IS DEBURRING?

What is Deburring? What is the Deburring Process? Exploring Deburr Techniques, Deburring Challenges, and Deburring Solutions!

What is the deburring process?

Exploring Deburr Techniques, Deburring Challenges, and Solutions!

Imagine crafting external gears that mesh seamlessly, internal gears that turn smoothly, or gearboxes that power machines with precision. The secret sauce to this seamless operation? It's all about deburring, a crucial but often underestimated process.

When you dive into manufacturing parts like external gears, internal gears, pinions, pinion shafts, or gearboxes, you're essentially crafting the building blocks of functionality. Every imperfection, no matter how small, can impact the overall performance. That's where deburring steps in, ensuring that these components meet the highest standards of quality and reliability.

Detail of a metal burr. Metal burrs must be removed to ensure safety, functionality, quality control, and optimal performance of metal gears or components in engineering applications.

Understanding Deburring

What is deburring? Deburring is the method of removing unwanted burrs—tiny, often sharp, imperfections—from machined parts. These burrs can result from various manufacturing processes like CNC machining, plasma cutting, or casting. If left untreated, burrs can compromise part functionality, aesthetics, and safety.

Types of Deburring Techniques

Exploring Deburring Techniques and Challenges

Manual Deburring: This traditional method requires skilled operators using tools like scrapers, files, and brushes to remove burrs. While it allows for precision, it is labor-intensive and can be time-consuming, limiting its scalability for large production volumes.

Machine Deburring: Automated deburring machines offer consistent and efficient burr removal, making them indispensable in modern manufacturing. However, challenges such as complex part geometries and varied burr sizes require advanced technologies for optimal results.

Chemical Deburring: While effective for selective burr removal, chemical deburring demands careful handling of chemicals and disposal, requiring strict adherence to safety and environmental regulations.

Abrasive Deburring: Utilizing abrasive materials for mechanical burr removal can generate heat and friction, leading to potential surface damage or tool wear over time.

Electrochemical Deburring (ECM): Although precise, ECM setups can be costly to implement and maintain, requiring skilled technicians for operation and maintenance.

Thermal Deburring: While effective, thermal deburring methods like flame deburring may introduce heat-related distortions in parts, necessitating additional quality control measures.

Cryogenic Deburring: While innovative, cryogenic deburring requires specialized equipment and expertise in handling cryogenic fluids, adding complexity and cost to the process.

Ultrasonic Deburring: While capable of reaching intricate areas, ultrasonic deburring may struggle with harder materials or thicker burrs, requiring adjustments or supplementary processes.

Brush Deburring: While versatile, brush deburring methods may require frequent tool changes or maintenance, impacting production uptime and efficiency.

Waterjet Deburring: While precise and non-destructive, waterjet deburring may struggle with certain materials or intricate geometries, requiring careful process optimization.

The best machine deburring solution combines multi-axis capability with compliant technology. Unlike rigid robotic systems, multi-axis machines with compliant features offer greater flexibility to adapt to varying part geometries and burr locations. They can adjust tool angles and pressures dynamically, ensuring consistent and precise deburring across different parts. Additionally, machines with various tool options provide versatility, allowing for the use of different deburring methods depending on the part's specific requirements. This flexibility translates to improved productivity, reduced setup times, and enhanced overall quality in the deburring process.

Challenges in Deburring

Despite its importance, deburring poses several challenges:

Complex Part Geometries: Components like external gears, internal gears, and gearboxes often feature intricate geometries, making manual deburring impractical and time-consuming.

Burr Consistency: Burrs can vary in size, shape, and location, requiring tailored deburring solutions for optimal results.

Time and Cost: Manual deburring is labor-intensive and prone to inconsistencies, leading to increased production time and costs.

Automated Deburring Solutions

Automated deburring machines equipped with multi-axis compliant technology, like The MAX, offer unparalleled advantages over traditional deburring methods.

Here's a closer look at why they stand out:

Precision: Multi-axis compliant technology integrates CNC deburring tools into automated machines, ensuring precise burr removal even in complex part geometries like pinions and pinion shafts. This precision enhances part quality and functionality, meeting industry standards effectively.

Consistency: These machines deliver consistent results across batches, reducing rework and ensuring consistent part quality. This reliability is crucial for maintaining product integrity and customer satisfaction.

Efficiency: By automating the deburring process, manufacturers save time, reduce labor costs, and boost overall production efficiency. This efficiency improvement is key for meeting production targets and staying competitive in the market.

Flexibility: Multi-axis compliant technology allows for versatile tool movements, adapting to different part shapes and sizes seamlessly. This flexibility optimizes workflow and resource utilization, enhancing productivity and reducing downtime.

Quality Assurance: With precise control and monitoring capabilities, multi-axis compliant machines ensure stringent quality standards are consistently met. This quality assurance is vital for industries demanding precision and reliability, such as automotive, aerospace, and medical device manufacturing.

The integration of multi-axis compliant technology elevates deburring processes to new levels, offering unmatched precision, consistency, efficiency, flexibility, and quality assurance in modern manufacturing environments. These advantages make them indispensable tools for achieving superior results in part finishing and production optimization.

Choosing the Right Deburring Equipment

When selecting deburring equipment, consider factors such as part complexity, production volume, and budget. Consult reputable deburring machine manufacturers like James Engineering, the deburr master known for their innovative deburring solutions tailored to various industries' needs. Top manufacturing companies go to the deburring experts for the best deburring machines.

Need a Chamfering Machine? Click Here

Burr Removal Methods

Exploring Deburring Tools and Techniques

When it comes to precision manufacturing, the right deburring tools and techniques are essential for achieving flawless finishes and optimal part functionality. Let's delve into the various deburring tools and their unique capabilities:

Deburring Brushes: Specialized brushes designed for deburring tasks effectively remove burrs from machined parts, ensuring smooth and precise edges crucial for product quality and performance.

Abrasive Wheels: Utilizing abrasive materials, such as grinding wheels or belts, abrasive deburring tools remove burrs and imperfections from metal surfaces, providing a consistent and uniform finish.

Chamfering Tools: Chamfering tools bevel edges, improving part aesthetics and reducing sharp edges, enhancing safety during handling and assembly processes.

Radius Forming Attachments: These attachments create precise radii on parts, essential for components like gearboxes and mechanical parts where rounded edges are critical for functionality and longevity.

Polishing Equipment: Polishing tools and materials, such as polishing brushes or compounds, achieve high-quality surface finishes, enhancing part appearance and meeting stringent industry standards.

Filing Tools: Filing tools are used to remove excess material and refine surfaces, maintaining precise dimensions and ensuring smooth edges for seamless part integration.

Washing Systems: Integrated washing systems clean parts thoroughly, removing debris, contaminants, and residual materials post-deburring, ensuring optimal cleanliness for subsequent processes or assembly.

In conclusion, understanding the deburring process, utilizing advanced deburring machines and tools, and choosing the right deburring method for your application are crucial steps in ensuring high-quality, precise machined parts.

By prioritizing deburring before chamfering, polishing, or other finishing processes, manufacturers can uphold the standards necessary for top-notch products in industries relying on precision components like automotive, aerospace, and machinery manufacturing.

If you are looking for the best deburring machines that have stood the test of time for their durability and used by top manufacturing companies across the world for chamfering and all purpose gear and part finishing.

Contact James Engineering at Sales@James-Engineering.com

The Future of Automation in Manufacturing | Machines vs. Human Labor

As manufacturing landscapes evolve, automation emerges as a crucial solution for optimizing processes like deburring and chamfering. This article explores the pressing need for automation in manufacturing, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

Automation in Part Manufacturing

As manufacturing landscapes evolve, automated deburring emerges as a crucial solution for optimizing processes like machine deburring and machine chamfering. This blog explores the pressing need for automated deburring, the challenges faced by human labor, and the limitations encountered with traditional robotic systems.

The Need for Automated Deburring in Part Finishing

Modern manufacturing demands high levels of efficiency and precision, especially in tasks like deburring and chamfering critical for part quality. Human labor, while skilled, faces challenges such as fatigue, variability, and safety risks. These factors hinder consistent production output and quality assurance, necessitating a shift towards automation.

Challenges of Human Labor

Limitations and Safety Concerns

Manual hand deburring and chamfering tasks are time-consuming and physically demanding, leading to potential errors and variability in results. Moreover, human operators face safety risks associated with handling sharp edges and heavy machinery, impacting both productivity and worker well-being.

Challenges of Industrial Robots

Rigidity and Adaptability

Traditional industrial robots, while efficient in certain tasks, often lack the adaptability required for complex deburring and chamfering processes. Their rigid programming limits flexibility, leading to challenges in handling diverse workpiece geometries and achieving consistent results across different parts.

Focused Deburring

Precision and Adaptability in Automated Deburring

James Engineering experts emphasize the significance of compliant technology in addressing these challenges. Their patented Focused Deburring can adapt to varying workpiece geometries, ensuring precise and consistent results without constant manual adjustments, or the need to mask parts. This adaptability reduces errors, enhances quality control, and streamlines manufacturing processes. Ensuring the next level of precision in deburring machines.

Integrating Automation for Sustainable Manufacturing

The evolution of manufacturing hinges on integrating automation solutions that combine efficiency, precision, and safety. By addressing the limitations of human labor and traditional robotic systems, manufacturers can achieve higher productivity, quality assurance, and workforce empowerment. Experts like James Engineering offer valuable insights and solutions that pave the way for a sustainable and innovative manufacturing future.

See the different system options here.

Contact us to determine which system best suits your manufacturing needs.

The Power of Compliant Technology, the Magic Behind The MAX

There’s major problem in the industry! Find out how we solve it!

See how James Engineering is solving the problem of non-inform parts , watch the video below

Precision is key.

Yet, the reality often falls short of the ideal, with parts turning out to be anything but perfect. Scott Richards, Vice President of James Engineering, delves into the heart of this challenge, shedding light on the industry's persistent problem and the innovative solution James Engineering has developed.

Solving the Problem of Non-Uniform Parts

Watch below as Scott Richards opens the discussion by addressing a common yet critical issue in manufacturing: non-uniformity. Many parts, despite appearing round, lack uniformity in dimensions. This discrepancy poses a significant challenge, particularly in processes like deburring, where precision is paramount.

Traditional approaches, including vision systems and CNC machines with complex algorithms, have failed to adequately address this issue over the past four decades. However, James Engineering's breakthrough compliant technology offers a revolutionary solution.

The Essence of Compliant Technology

Compliant technology mimics the human hand's ability to sense and adapt to surfaces in real-time. Unlike conventional methods reliant on lasers or mathematical equations, compliant technology mechanically senses and reacts to surface variations as they occur. This approach eliminates the need for predictive algorithms and ensures consistent results, even with perishable tools prone to uneven wear.

Navigating the Challenges of Inconsistent Parts

Watch as Scott delves deeper into the complexities of inconsistent parts, emphasizing the significant impact of stress relief in machining processes. As parts undergo machining, stress relief can cause unexpected distortions, leading to mismatches between the intended model and the final product. This disparity poses challenges for CNC machines and robots programmed to expect uniformity.

Addressing the Inconsistency

James Engineering's compliant technology offers a versatile solution to address inconsistencies across various manufacturing processes. By dynamically adjusting to surface variations, the technology ensures precise results, regardless of a part's shape or dimensions. Unlike traditional methods reliant on human intervention, compliant technology offers unparalleled accuracy and repeatability, enhancing overall manufacturing efficiency.

Empowering Manufacturers with Precision

In a competitive manufacturing landscape, precision is non-negotiable. James Engineering's compliant technology empowers manufacturers to achieve unparalleled precision and consistency, revolutionizing traditional manufacturing processes. By eliminating the reliance on manual intervention and predictive algorithms, the technology streamlines operations, reduces costs, and enhances product quality.

Embracing the Future of Manufacturing

As industries evolve and technology advances, embracing innovative solutions becomes imperative for sustained success. James Engineering's compliant technology represents a paradigm shift in manufacturing, offering a glimpse into the future of precision engineering.

Scott Richards's insights into the transformative potential of compliant technology underscore its significance in revolutionizing manufacturing. By bridging the gap between traditional methods and emerging challenges, James Engineering paves the way for a new era of precision and efficiency in manufacturing.

Incorporating compliant technology into manufacturing processes holds the promise of unlocking new possibilities and driving unprecedented levels of efficiency and precision. As industries continue to evolve, embracing such innovations will be crucial for staying ahead of the curve.

Chamfer Explained - What is the Purpose of a Chamfer?

Chamfering’s importance is paramount in various fields such as civil engineering, woodworking, and machining. But what exactly is chamfering and what is its purpose?

Chamfering in Engineering

Chamfering’s importance is paramount in various fields such as civil engineering, woodworking, and machining. But what exactly is chamfering and what is its purpose?

Chamfer Definition

Chamfering refers to the process of creating a symmetrical edge by removing a right-angled corner or edge. Depending on component size, this may seem like a simple adjustment, but its implications are profound. Especially in industries like aerospace, automotive, etc; where precision is a must.

(Before/After)

Deburred and Chamfered with a James Engineering Max System

What is The Purpose of Gear Chamfering?

If parts and gears are left with no chamfer sharp angles can exist, posing a serious risk to operability and safety. These angles become stress points and the component becomes vulnerable to damage and fatigue. In machining, impacts, vibrations, and extreme heat exacerbate these risks and can lead to breaks or fractures. Damage like this can impact the performance of the entire machine. With a chamfer, the stress of the sharp edge is appropriately distributed and the risk of damage is eliminated.

Reducing Stress with a Chamfer

As an example, consider a 90-degree angle. Chamfering the angle flat and creating two 45-degree angles significantly decreases the stress of that edge. This minor altercation greatly extends the lifespan of components, ensuring durability and reliability.

90° angle cut to two 45° angles to remove stress point.

Optimizing the Gear Chamfering Process

Even though a chamfer is only a slight alter, chamfering can be a very tedious, time-consuming, and inconsistent process. However, advanced technologies have revolutionized this process. With our MAX automatic and manual gear chamfering machines, chamfering is no longer a challenge–it’s a seamless operation.

Our gear chamfering machines are engineered for an operator of any experience without compromising on precision, quality, efficiency, or sustainability. Whether it’s a large-scale project or a small intricate detailed job, our unique machines are tailored to meet any need. We specialize in custom solutions, whether it’s large single-part batches or varying parts in each cycle, we will fully optimize your process.

Conclusion

Chamfering plays a vital role in enhancing the performance and longevity of components across various industries. By understanding chamfering’s purpose and utilizing advanced technologies, engineers can ensure that their products will withstand the test of time. Reach out to learn how MAX and manual machines can optimize your chamfering process and elevate your operation to new heights.

Chamfer Explained 3D Animation

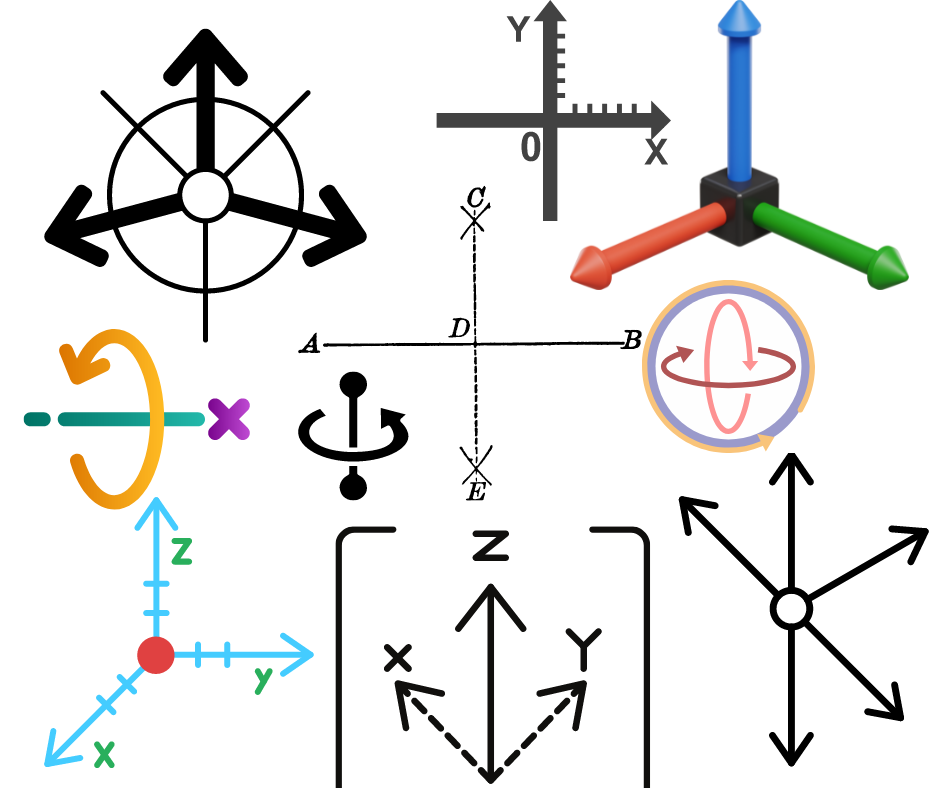

The Advantage of 11-Axis Machining over 5-Axis Machining in High Precision Part Finishing

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

In the realm of manufacturing, precision is paramount. Achieving high precision in part finishing not only enhances the quality of the final product but also significantly impacts efficiency and cost-effectiveness. Traditional machining methods have paved the way for advanced technologies like 5-axis machining, and now, the evolution continues with the advent of 11-axis machining. In this article, we delve into the nuances of high precision part finishing and explore the distinct advantages offered by 11-axis machining over its 5-axis counterpart.

Understanding High Precision Part Finishing

High precision part finishing involves the intricate process of refining components to exact specifications, ensuring dimensional accuracy, surface finish quality, and overall performance. This meticulous craftsmanship is vital across diverse industries, including aerospace, automotive, medical devices, and beyond, where precision is non-negotiable.

5-Axis Machining: A Step Forward

5-axis machining revolutionized manufacturing by enabling simultaneous movement of the cutting tool along five axes, allowing for enhanced complexity and flexibility in part production. This technology excels in sculpting intricate geometries and contours with remarkable accuracy, reducing setup time and increasing efficiency compared to traditional 3-axis machining.

The Emergence of 11-Axis Machining and Beyond

Building upon the capabilities of 5-axis machining, Multi-axes machining represents the next frontier in precision manufacturing. By incorporating additional rotational and tilting axes, this advanced technology introduces unprecedented levels of versatility and precision to part finishing processes.

Experience precision in action with James Engineering’s state-of-the-art 11-axis 2 Tower , The MAX, all purpose finishing machine – revolutionizing part finishing for top-tier quality and efficiency.

Benefits of 11-Axis Machining over 5-Axis

Enhanced Complex Geometry Machining: With six additional axes at its disposal, 11-axis machining offers unparalleled freedom in maneuvering the cutting tool around complex part geometries. This capability is particularly advantageous for producing intricate components with challenging features, such as undercuts, draft angles, and compound curves.

Optimized Surface Finish: The increased flexibility of 11-axis machining enables precise control over tool paths and cutting angles, resulting in superior surface finish quality. Fine details and delicate features can be meticulously refined, eliminating the need for secondary finishing operations and reducing overall production time.

Improved Tool Accessibility: Complex part geometries often present challenges in tool accessibility during machining. 11-axis machines address this issue by enabling dynamic tool positioning from multiple angles, ensuring optimal reach and coverage across the entire workpiece. This capability minimizes the need for repositioning and mitigates the risk of tool interference, enhancing overall process efficiency.

Streamlined Setup and Fixturing: By reducing the reliance on elaborate fixturing and setup arrangements, 11-axis machining simplifies the preparation process for part finishing. The increased range of motion allows for more flexible workholding solutions, optimizing workflow and reducing setup time and associated costs.

Enhanced Productivity and Cost Efficiency: The precision and efficiency afforded by 11-axis machining translate into tangible benefits for manufacturers. By minimizing material waste, improving cycle times, and reducing the need for secondary operations, this technology streamlines production workflows and enhances overall productivity while maintaining competitive pricing.

The Future of Machining

In the pursuit of precision manufacturing, the transition from 5-axis to Multi Axis machining represents a significant leap forward. By unlocking new levels of versatility, accuracy, and efficiency in part finishing processes, Multi-Axis machining empowers manufacturers to push the boundaries of innovation and meet the exacting demands of modern industries. As this technology continues to evolve, its transformative impact on precision manufacturing will undoubtedly shape the future of the industry, driving advancements in product quality, performance, and competitiveness.

Contact James Engineering on how multi-axis machining can improve your cnc manufacturing process. Sales@James-Engineering.com