CASE STUDY: Manufacturing Customer Survey Finds The Following Results

In 2011, we conducted a client survey of over 1500 manufacturers, across varied industries doing manual and hand deburring.

How Much Production Time Are You Losing?

Set up? Processing Time? The MAX speeds all of this!

FASTEST CHANGE OUTS:

This doesn’t even include the faster processing time of each part... If you deburr 250 parts a month, you could save approximately 120 hours in setup time alone.

How much production time are you losing?

Set up? Processing Time? The MAX speeds all of this!

Once a setup is made, it is saved as a recipe.

Recipes are called up by filename instantly.

No Changeover or setups!

*As an option, we also offer auto-part ID.

Lower your Cost Per Part!

The MAX Systems are ideal for applications where parts are run on a repeat basis. The frequency and

volume is not important. In other words, you can run a different part every single cycle as long as

the parts are re-run at some point; even if it is five years down the road. Your saving yourself time and money!

Fastest Cycle Times in the Biz!

Run a different part every cycle!

Automatic Wheel Wear Compensation

Chamfer, Radius or any other type of edge finish

It has been about five years since we bought your deburring machine. I can boast that we have greatly improved the quality of gears as opposed to hand deburring. The productivity is unmatched! Many of the parts used to take 30 minutes by hand and now the same part is done in about 30 sec.

— Ramdas Amin, Mfg Engineer, GE Aviation Systems

I have been using a James Engineering 462 for about 4 years now. It works wonderful I can’t imagine working without that machine. It has done our company justice!

— Tim Fuller, Manufacturing Engineer, Baldor

We have benefited from faster set-up times to faster cycle times. The machine has functioned effectively without failure ever since we powered it up in 2005.

It is extremely easy to set up on spiral bevel ring gears and many other parts we manufacture.

We highly recommend it for any company interested in improving their deburring processes

— Paul Campion, GM, Reliance Gear

See more of our customers here.

The Machine Shop at James Engineering

Get an inside scoop about the machine shop at James Engineering from a Q&A with lead engineer, Dave Schlosser, and company vice president, Scott Richards.

The Colorado-based OEM shop is known for their one-of-a-kind deburring and chamfering machines, but they also have a precision-focused machine shop that’s willing to take on any project that comes their way. If you’re in the market for a low to medium volume machine shop who guarantees quality products, reach out to James Engineering today at (303) 444-6787.

—

What is our shop capable of?

Dave: We have 3 mills and 2 lathes. One of the mills has 4th axis capability. We’re capable of holding concentricity within 5/10ths in most cases without have to do any crazy set ups. We can do round parts, square parts, just about any shape part that you want.

Scott: We’ve got a live tool lathe with a bar feed option and multiple seats of programming software. We’ve got that 4th axis mill, another smaller mill with a 20-inch bed, and we’ve got a 60-inch bed large mill.

How many parts a week do we typically make?

Dave: That’s pretty subjective because we do short run production, so most of our time isn’t spent making parts, it’s getting ready to make a part and getting a part set up to run. Typically, we could spend half hour programming, half our setting up, and basically we could run for 15 minutes and then be done (in some cases). We can’t really quantify the quantity of parts per week because we’re more set up to be a tooling or prototype shop versus a production shop.

Can customers send in their own designs?

Dave: We quote on stuff and have stuff made for outside companies. We have engineering services, so people can send in a concept and we could do the whole thing, or they could send in a thing that’s basically done and we could create drawings for them, things like that. We have start-to-finish capability, or we can pick up a project that they’re already halfway through. We can also provide good drawings, give them a model.

What are some basic jobs we do frequently?

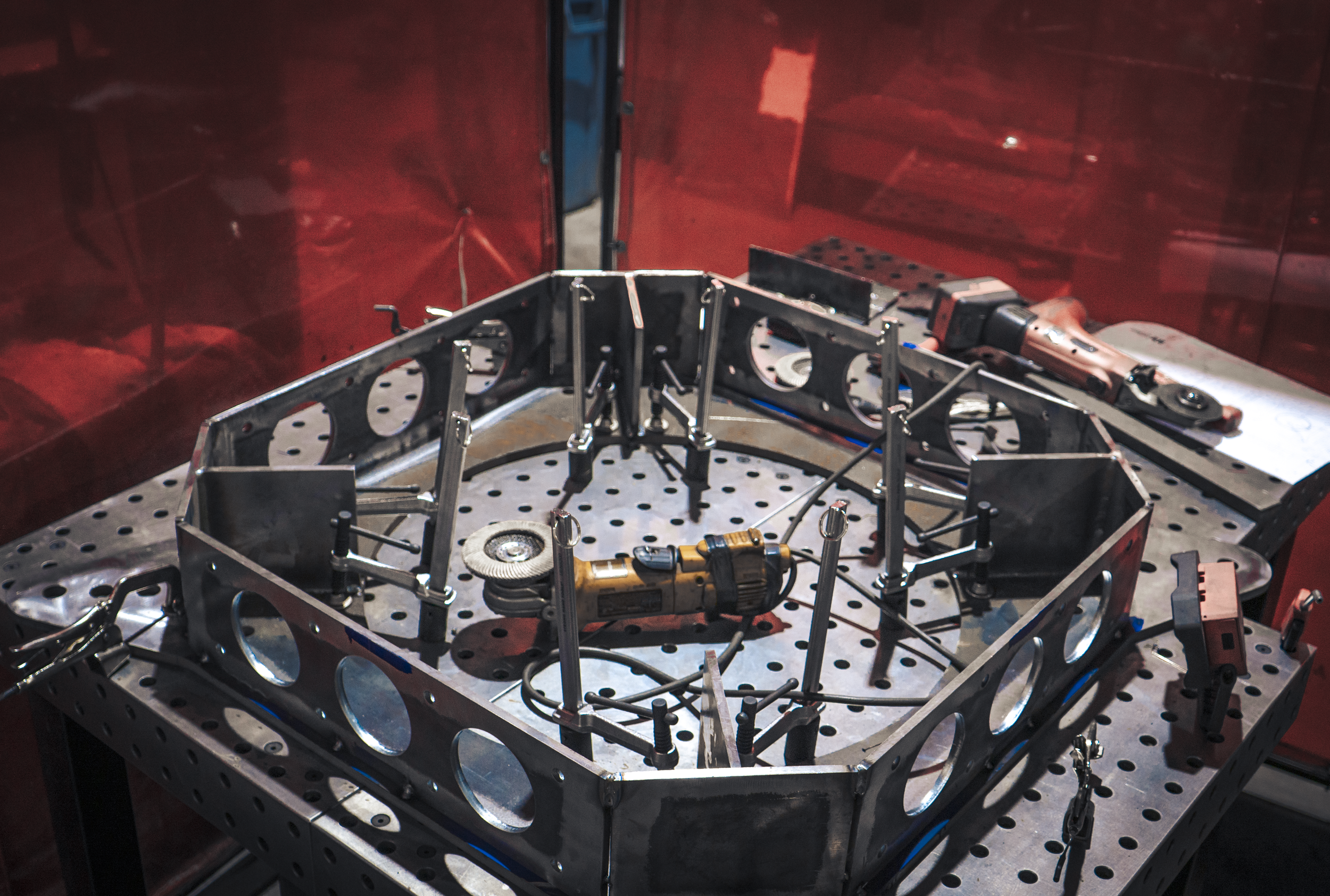

Dave: We do a lot of gun parts, automotive stuff, motorcycle parts. It really is just a gamble. Basically, anybody who walks into the door with a project, we can take a look at it and see if it fits our capabilities fairly easy and we’ll do it. We’ve done a lot of welding jobs lately, too. We’ve done a lot of stuff for RoboCon; we’ve made a lot of platforms and fixturing. We’ve made brownie bowls, and stuff for volleyball companies, it doesn’t really matter what industry comes in.

Scott: So we’ve got a lot of high end, high precision parts that we make. For example, we’re making a mount for a vehicle right now. Our perfect job is a volume job. We’re really looking for anything from prototype to a few thousand parts a week. I wouldn’t call ourselves high volume where we’re tens of thousands of parts per week, but we’re definitely looking for that low to medium volume area.

What makes our shop stand out?

Dave: Our attention to detail and the quality of our parts. That’s something that we take a lot of pride in. We try to go that one step above, whether it’s by deburring or not putting a scratch on it by pushing it across surfaces, things like that. We take really good care of all the parts we make, and it’s a lot easier to go in and get the quality you’re looking for when you’re not making thousands and thousands of parts.

Why is it significant for our machine side of business that we make our own parts in-house?

Dave: We can control our own quality because our standards are really high. To be able to get the tolerances and stuff we need we can hardly get other people to make them for us. We put a dimension on a drawing and expect you to hold it, so in some cases we put really tight tolerances on things with reason, and when other companies see those tight tolerances the cost goes up automatically (whether it’s justifiable or not). It’s more cost efficient for us to do it.

Scott: We have to make all of these parts here in-house because we really can’t afford to job much of this out. We’ve got to keep our profit margins where they need to be. We have to hold pretty precision fits because we’ve got a 3.2 million resolution encoder here turning all of these [parts] on this five-axis manipulator.

How do your own deburring machines fit into the machine shop process?

Scott: When we make these parts, we do a lot of in-machine deburring. We’ll go through and we’ll machine this edge with a chamfer tool. But the problem is, when we machine the edge with the chamfer tool, the chamfer tool creates two sharp edges. We still have this problem where a technician has to go in with Scotch-Brite and deburr this. So we don’t want that abrasive to get into our CNC machine, because if that abrasive gets into our machines, it gets down into ways and slides and it wears the machine out. That’s where the market is for our deburring machine.

The Difference Between Grinding, Polishing, and Deburring

These three machining processes all seem frustratingly similar—so what makes them different from each other?

Grinding, polishing, and deburring—anybody who knows anything about the precision machining process knows that these three processes are a.) crucial, and b.) acts of surface finishing. These three processes are very similar to each other, and for decades have been making people ask the same questions: What’s the difference? And why do we need to do all three processes? Both of these questions are valid, and we have the answers to both below.

The difference between grinding, polishing, and deburring.

1. Grinding

This is the process of removing material and shaping a workpiece into its final form. Grinding can be done on a multitude of materials, such as plastic, ceramic, and many different metals (stainless steel, titanium, high-nickel alloys, etc.). In order to complete this process, grinding wheels of different abrasives are used in various machines made specifically for grinding. It’s important that the correct kind of abrasive is used, as too soft of an abrasive can’t grind a workpiece enough, while too hard of an abrasive will damage a workpiece and result in decreased part quality or scrapped part. Overall, grinding is essential because it improves a part’s surface finish, which not only provides the aesthetic many industries require, but also ensures the removal of pesky surface imperfections.

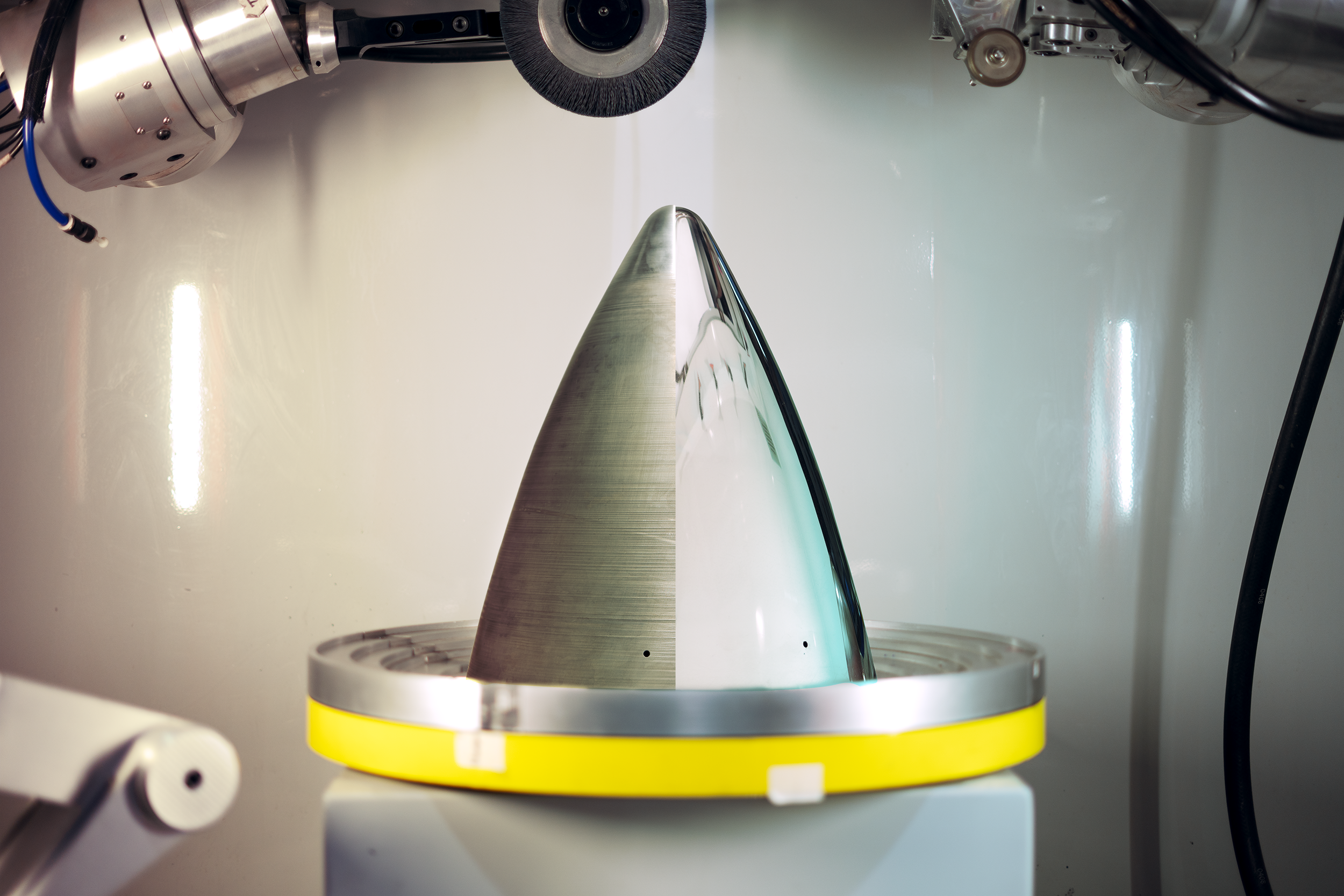

2. Polishing

Polishing is the process surface finishing, which is also known as the process of improving surface quality. Using softer, smaller abrasives like polishing compounds and wheels, surface imperfections such as scratches and unwanted film/layers are removed to achieve a part’s desired texture (as different industries require different surface finishes). Polishing can be done by hand, machine, or robot, as it doesn’t require quite as much precision as grinding or deburring do. This step can be taken farther with buffing, which gives parts a finish similar to that of a mirror.

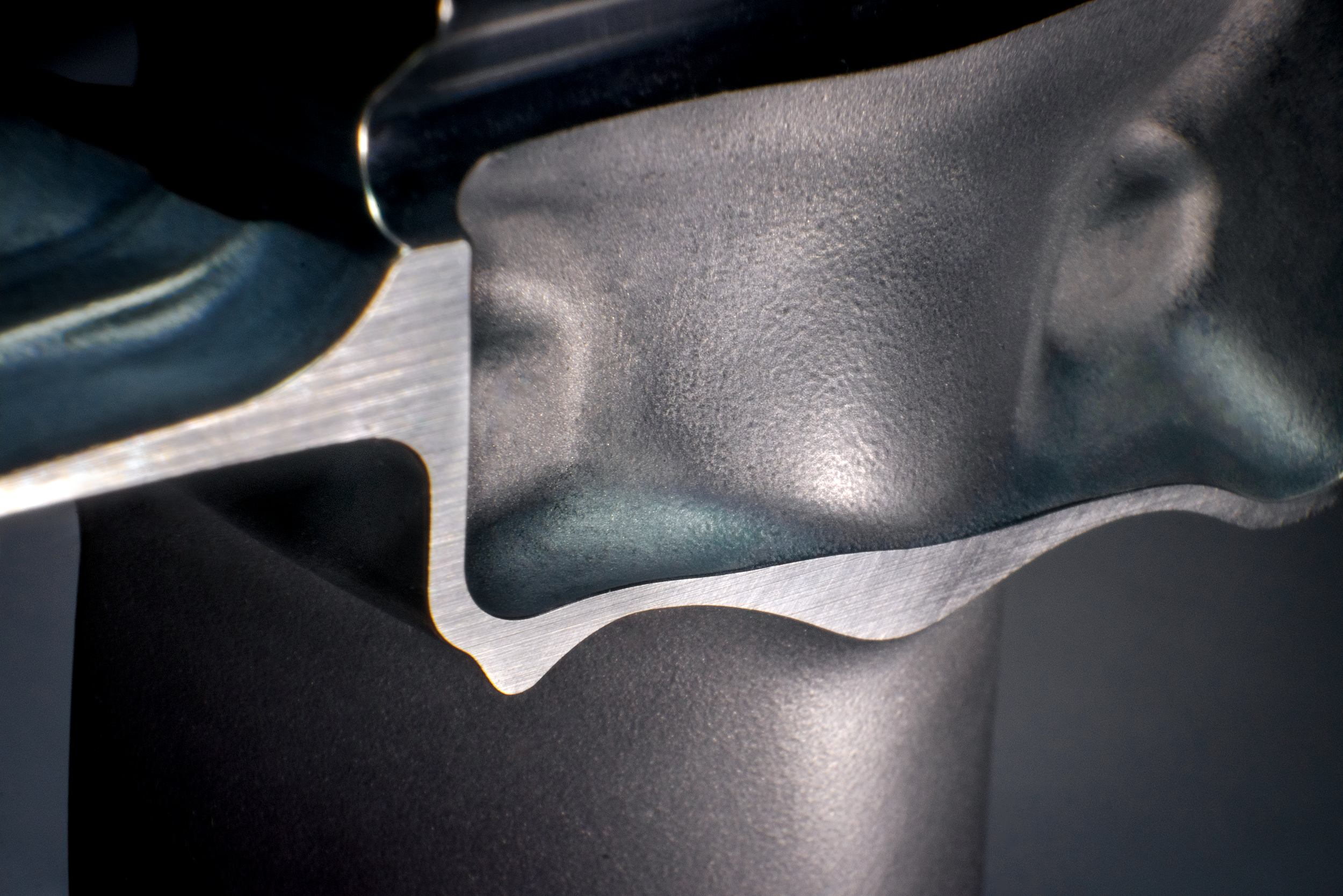

3. Deburring

This process is the act of removing burrs from a part’s surface. Burrs are extra bits of metal that form as a part is being cut, and can be extremely harmful both for a part’s functionality and the overall assembly it’s a part of. Deburring can be done by hand or in a machine, though hand deburring proves to be inconsistent and costly. The process of deburring requires extreme precision, as any leftover bit of metal can cause inconsistencies that result in the decrease of a part’s longevity and efficiency. Deburring is required for any part that has been previously machined and can be done on a variety of different materials, such as ceramic, stainless steel, wood, titanium, and more. What makes it an essential process is it ensures parts meet industry standards and helps reduce the possible formation of stress risers.

Surface Profiling

Seeing as all three of these processes fall under surface finishing, it’s important to know how surface finish is measured. Surface profiling is the measurement of a surface’s roughness, which allows manufacturers to know how adequately prepared a part is for further processing, especially when it comes to the part coating and assembly stages. A profilometer is the tool used to measure these surfaces and can be split into two categories: contact and non-contact. Contact profilometers use a stylus to map out the highs and lows of the surface (also known as peaks and valleys) which allow operators to gauge how smooth or rough a workpiece surface truly is. A non-contact profilometer uses image sensors to detect a surface’s texture. While this is the faster of the two profilometers, it’s extremely sensitive to any dirt or oil that may be coating a part’s surface.

Why does manufacturing require all three processes?

Ultimately, grinding, polishing, and deburring are all needed for the same reasons: dimensional accuracy, part efficiency, corrosion resistance, and improved functionality. All of these processes refine parts so they’re safe, functional, and meet industry standards. In other words, it’s the manufacturing equivalent of editing a piece of writing before publishing. A part might work fine enough after it’s just been cut, but without grinding, polishing, and deburring, it probably won’t fit into its assembly correctly, and it certainly won’t reach its ultimate level of efficiency and precision. The time and energy spent on these three process ensure that overall assemblies will require less maintenance, which saves operators and businesses precious time and money.

The Machine that can do it all

One of the most efficient ways of grinding, polishing, and deburring on the market is by using the MAX, an all-encompassing finishing machine sold and manufactured by James Engineering. This deburring and chamfering machine is capable of carrying out all three process concurrently. This means a part can be deburred, ground, and polished in one go. This machine also has a consistent precision unreachable by any hand-done method or other machine. The MAX makes all three processes easy and affordable, which ultimately revolutionizes any operation.

To watch the MAX in action, check out the James Engineering YouTube channel here.

To inquire more about the MAX, call (303) 444-6787 today.

What Is Gear Chamfering?

In simple terms, gear chamfering is the process of cutting a 90-degree edge at a 45-degree angle, but in reality it’s a bit more complicated than that.

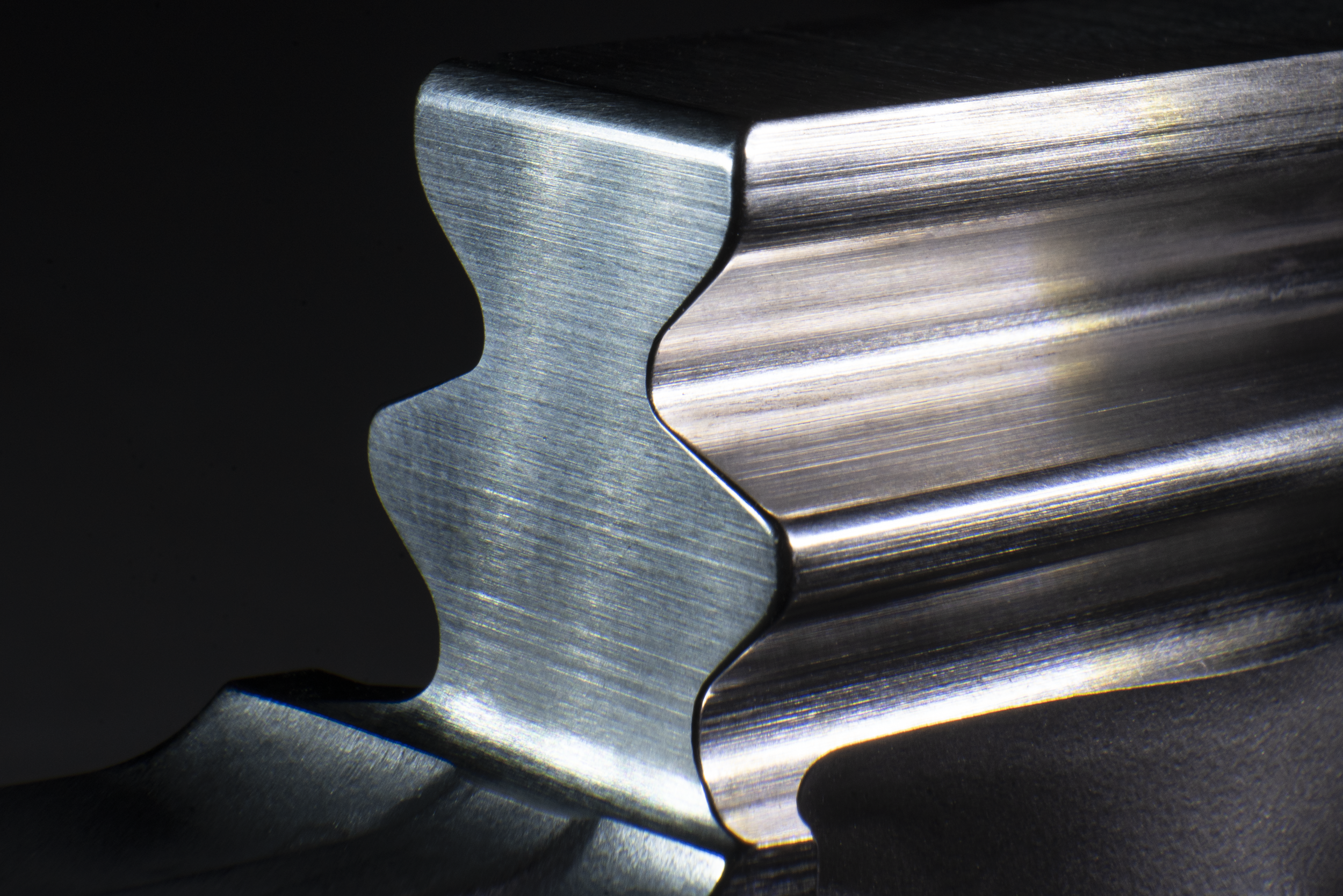

Simply put, the process of chamfering is cutting a 90-degree edge at a 45-degree angle as a way to remove stress-rising sharp edges, as well as allow for smoother assembly. That makes chamfering sound easy, when in reality it’s actually very time consuming, no matter the method of approach.

Gear Chamfering can truly be broken down into four separate surface-finishing processes: deburring, chamfering, radiusing, and radius-chamfering.

- Deburring is the process of grinding off burrs, which are bits of excess metal created in the metal cutting process. Burrs are extremely problematic and will cause issues in assembly as well as overall part efficiency. Assuming the deburring has been done properly, all burrs will have been completely removed, leaving nothing but a sharp edge.

- Chamfering, as stated above, is the process of cutting that sharp edge at a 45-degree angle (which is the most common angle, but not the only one they’re limited to). Chamfering can be done with a myriad of tools, such as brushes, sandpaper, grinding wheels, and Scotch-Brite. However, in the process of shaving down this one sharp edge, two more are created on either side of the original, and if the tool being used is worn down, burrs can be created as well.

- Radiusing is the process of completely rounding out edges until it’s completely smooth. While chamfering is smoother than just leaving a part deburred, it still is cut at a noticeable angle that can be seen and felt. Radiusing feels and looks rounded (just like how a ball is round without any hard edge), and can also be carried out via brushes, grinding wheels, and sandpaper. It’s crucial to know what materials these tools are made out of, because the materials will affect the quality of the radius; if a material is too abrasive, it will be impossible to reach a true radius. A true radius is when the edges of a 90-degree angle go tangent to tangent without any surface imperfection.

- Radius-chamfering is when a part receives both radiusing and chamfering. The sharp angle is cut at the usual 45-degree angle, and when those two extra sharp angles are created, they are radiused to create smooth transitions between chamfers.

When it comes to how chamfering is done, there’s a few methods operators can choose from—machine-based, hand-based, or robot-based.

Different types of gear chamfering machines are capable of different sub-categories of chamfering. For example, a CNC machine can decently deburr a part, a lathe can adequately radius-chamfer a part, and a mill can chamfer a part. All of these options are valid, but not a single one of them can chamfer, deburr, and radius a part; separate machines are needed. Not only that, but these kinds of machines require in-depth programming for every single part in order to be exact. The MAX by James Engineering is capable of carrying out all four chamfering processes with heightened precision, as well as little programming.

Doing any of these processes by hand is technically achievable, but it ultimately proves to be more troublesome than it’s worth. Manufacturing is an industry that requires precision, as things will fall apart and fail to work correctly without it, and doing these processes by hand simply does not provide adequate enough precision. Even the best operator can slip or tremble, and man cannot repeatably guarantee a consistent chamfer. Hand chamfering is acceptable in a pinch, especially if only one or a handful of parts require it. But for higher volume operations, not only does hand chamfering not produce consistent results, it also is extremely time and cost inefficient. Scrap rates are the highest with hand chamfering, and the time it takes operators to complete one part is what it would take a CNC to do two or three, or the MAX to do a hundred.

Robots are only slightly better at gear chamfering than when done by hand. While they do have better mobility than most machines, they lack precision. Robots are perfect for operations that require the moving and placing of items, but they just cannot match a machine’s precision. Robots also require a lot of laborious programming, overall making them a poor method of chamfering.

Out of all these methods, the MAX is hands down the most reliable and efficient. As an all-encompassing finishing system, it is capable of deburring, chamfering, radiusing, and radius-chamfering any part or gear, no matter its complexity. It does require some initial programming, but once a part/gear has been loaded in, the MAX will remember it for future use, meaning operators no longer have to manually input adjustments themselves (James Engineering calls these programs “recipes”). The MAX is also capable of repeatable precision down to the fifth decimal. For reference, the average human hair measures to .003 inches. The MAX can repeatably work down to .00001 inches, and even beyond that.

Precision in chamfering is key, because the less precise a chamfer is, it’s more likely that stress risers will appear with continual usage. Stress risers are tiny cracks that form at a part/gear’s weakest point of contact (like the tooth on a gear). If a part is not adequately deburred or chamfered, what will happen is those sharp edges will slowly break off until a part or gear’s structure is ultimately compromised. So that previously mentioned tooth could fall off, for instance. That is extremely dangerous, both for the assembly itself and the people operating it. For example, a helicopter would crash if one of the gears in its motor failed. When it comes to chamfering, the higher the precision, the better. The precision achieved by the MAX means that parts/gears processed through it are extremely unlikely to form stress risers even after years of use.

There’s a misconception about chamfering that it’s done easily. Even with an advanced machine such as the MAX, chamfering is no “easy” feat. If a chamfering operation appears to be “easy”, it’s probably being done sloppily and inefficiently—and precision takes time and effort.

Knowing the correct way to chamfer is a gamechanger with any operation, as well as being able to recognize when a chamfer is done correctly. If it is, parts will fit together with no resistance and work efficiently for the entirety of their lifetime. And when parts work correctly, overall assemblies will perform at their best.

To visibly see how chamfering is done, watch a short video clip here.

To contact James Engineering about the MAX’s chamfering abilities, call at (303) 444-6787