Mastering Work-holding: The Advantages of Self-Centering Clamps

In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

In engineering and manufacturing, achieving precision and efficiency is not just desirable; it's crucial for success. As industries evolve, so do the tools and technologies used to streamline processes and save valuable time. One such innovation that has transformed the landscape of workholding solutions is the self-centering clamp. Let's explore their benefits and understand the uses.

Understanding Centering Clamps

Centering clamps, also known as engineering clamps, are indispensable tools in various industries where holding workpieces securely and precisely is essential. Traditionally, clamping mechanisms required meticulous adjustments to ensure proper alignment, often leading to time-consuming setups and adjustments. This is where self-centering clamps step in to revolutionize the game.

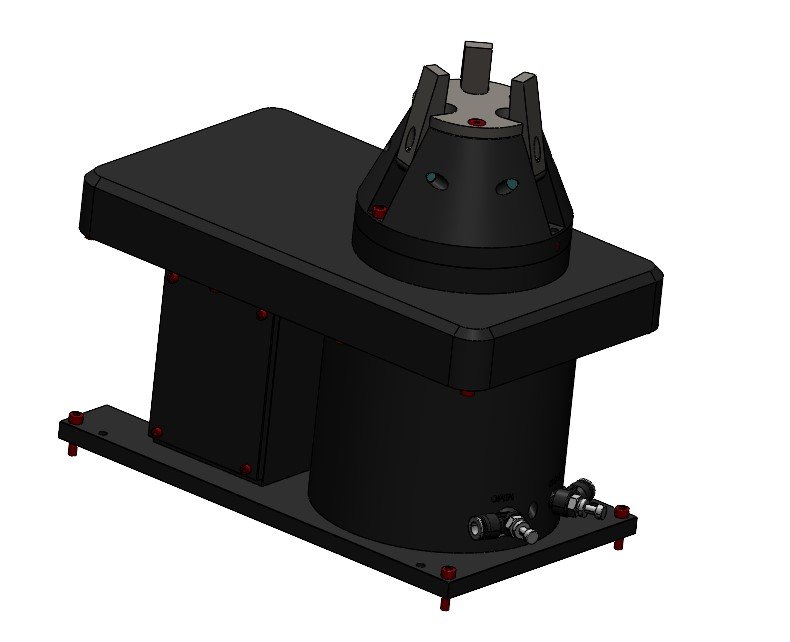

Unyielding strength in every grip. The JE heavy-duty Work Station is built to handle 1000+ pounds with ease.

Enter Self-Centering Clamps

Self-centering clamps stand out as a beacon of innovation in the realm of workholding solutions. These ingenious devices are designed to automatically center and secure workpieces with lightning-fast precision, eliminating the need for manual adjustments. This "quik-change" feature ensures lightning-fast change-outs, significantly reducing setup time and increasing productivity.

Time-Saving Benefits

Time is money, especially in the competitive landscape of manufacturing. With traditional clamping methods, precious minutes are spent on meticulous adjustments to achieve the desired alignment. Self-centering clamps, on the other hand, drastically reduce setup time by automatically centering the workpiece with unparalleled speed and accuracy. This means engineers and machinists can devote more time to actual production tasks, maximizing efficiency and output.

Labor Advantages

Labor optimization is another crucial aspect of any manufacturing operation. By incorporating self-centering clamps into the workflow, companies can streamline their processes and make more efficient use of human resources. With reduced setup times and simplified operation, skilled workers can focus on tasks that require their expertise, rather than repetitive manual adjustments.

Versatility and Reliability

Self-centering clamps are renowned for their versatility and reliability. See multiple versions here.

Whether in CNC machining, welding, assembly, or any other application requiring precise workholding, these clamps deliver consistent performance, ensuring repeatable results with minimal effort.

Conclusion

In conclusion, self-centering clamps represent a significant leap forward in workholding technology. Their ability to provide lightning-fast change-outs, coupled with the time-saving benefits and labor advantages they offer, make them indispensable tools in modern manufacturing environments. By embracing innovation and efficiency, companies can stay ahead of the curve and unlock new levels of productivity in their operations.

The Machine Shop at James Engineering

Get an inside scoop about the machine shop at James Engineering from a Q&A with lead engineer, Dave Schlosser, and company vice president, Scott Richards.

The Colorado-based OEM shop is known for their one-of-a-kind deburring and chamfering machines, but they also have a precision-focused machine shop that’s willing to take on any project that comes their way. If you’re in the market for a low to medium volume machine shop who guarantees quality products, reach out to James Engineering today at (303) 444-6787.

—

What is our shop capable of?

Dave: We have 3 mills and 2 lathes. One of the mills has 4th axis capability. We’re capable of holding concentricity within 5/10ths in most cases without have to do any crazy set ups. We can do round parts, square parts, just about any shape part that you want.

Scott: We’ve got a live tool lathe with a bar feed option and multiple seats of programming software. We’ve got that 4th axis mill, another smaller mill with a 20-inch bed, and we’ve got a 60-inch bed large mill.

How many parts a week do we typically make?

Dave: That’s pretty subjective because we do short run production, so most of our time isn’t spent making parts, it’s getting ready to make a part and getting a part set up to run. Typically, we could spend half hour programming, half our setting up, and basically we could run for 15 minutes and then be done (in some cases). We can’t really quantify the quantity of parts per week because we’re more set up to be a tooling or prototype shop versus a production shop.

Can customers send in their own designs?

Dave: We quote on stuff and have stuff made for outside companies. We have engineering services, so people can send in a concept and we could do the whole thing, or they could send in a thing that’s basically done and we could create drawings for them, things like that. We have start-to-finish capability, or we can pick up a project that they’re already halfway through. We can also provide good drawings, give them a model.

What are some basic jobs we do frequently?

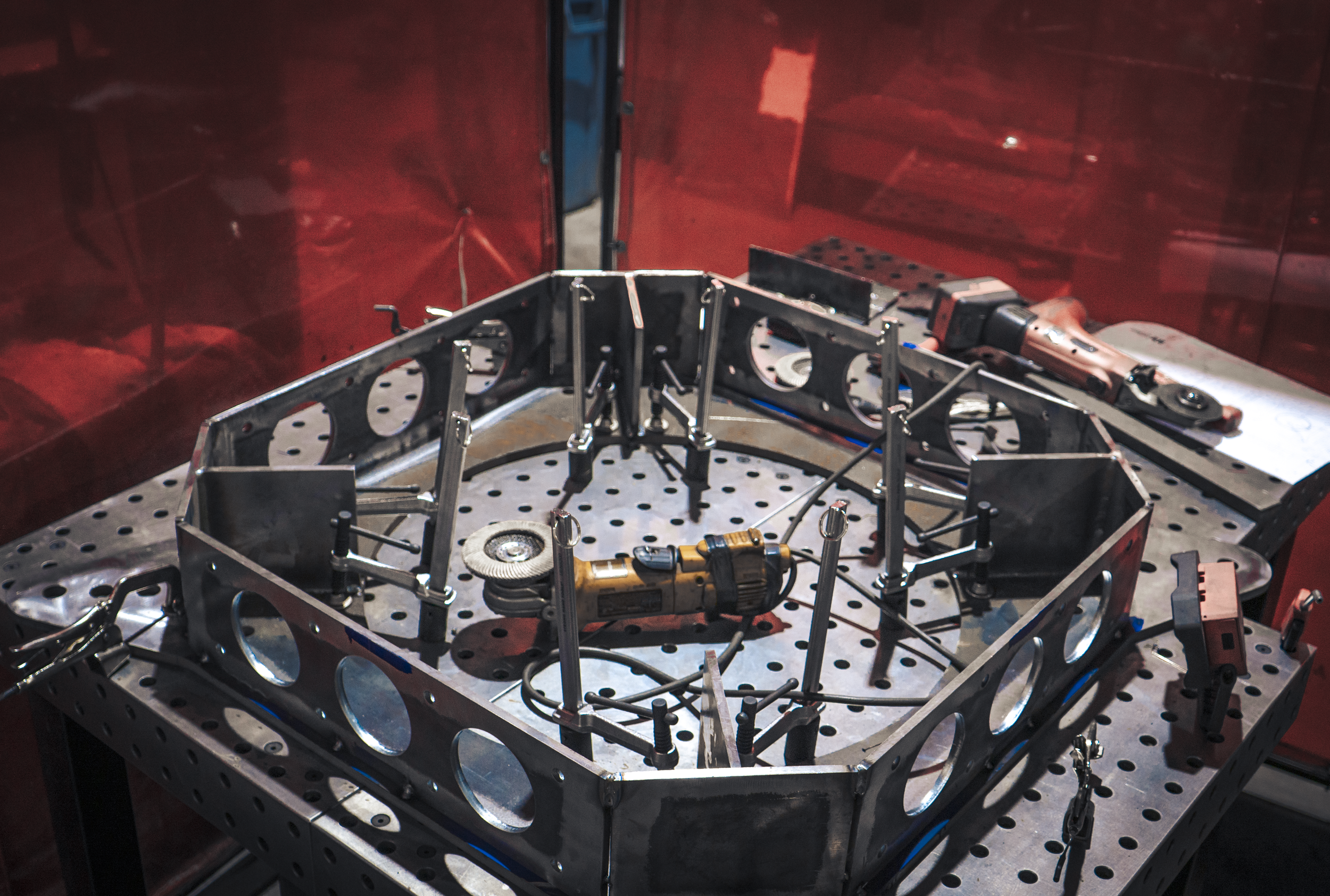

Dave: We do a lot of gun parts, automotive stuff, motorcycle parts. It really is just a gamble. Basically, anybody who walks into the door with a project, we can take a look at it and see if it fits our capabilities fairly easy and we’ll do it. We’ve done a lot of welding jobs lately, too. We’ve done a lot of stuff for RoboCon; we’ve made a lot of platforms and fixturing. We’ve made brownie bowls, and stuff for volleyball companies, it doesn’t really matter what industry comes in.

Scott: So we’ve got a lot of high end, high precision parts that we make. For example, we’re making a mount for a vehicle right now. Our perfect job is a volume job. We’re really looking for anything from prototype to a few thousand parts a week. I wouldn’t call ourselves high volume where we’re tens of thousands of parts per week, but we’re definitely looking for that low to medium volume area.

What makes our shop stand out?

Dave: Our attention to detail and the quality of our parts. That’s something that we take a lot of pride in. We try to go that one step above, whether it’s by deburring or not putting a scratch on it by pushing it across surfaces, things like that. We take really good care of all the parts we make, and it’s a lot easier to go in and get the quality you’re looking for when you’re not making thousands and thousands of parts.

Why is it significant for our machine side of business that we make our own parts in-house?

Dave: We can control our own quality because our standards are really high. To be able to get the tolerances and stuff we need we can hardly get other people to make them for us. We put a dimension on a drawing and expect you to hold it, so in some cases we put really tight tolerances on things with reason, and when other companies see those tight tolerances the cost goes up automatically (whether it’s justifiable or not). It’s more cost efficient for us to do it.

Scott: We have to make all of these parts here in-house because we really can’t afford to job much of this out. We’ve got to keep our profit margins where they need to be. We have to hold pretty precision fits because we’ve got a 3.2 million resolution encoder here turning all of these [parts] on this five-axis manipulator.

How do your own deburring machines fit into the machine shop process?

Scott: When we make these parts, we do a lot of in-machine deburring. We’ll go through and we’ll machine this edge with a chamfer tool. But the problem is, when we machine the edge with the chamfer tool, the chamfer tool creates two sharp edges. We still have this problem where a technician has to go in with Scotch-Brite and deburr this. So we don’t want that abrasive to get into our CNC machine, because if that abrasive gets into our machines, it gets down into ways and slides and it wears the machine out. That’s where the market is for our deburring machine.

Happy Manufacturing Day!

Today is National Manufacturing Day, and the beginning of Manufacturing Month! Let’s dive in to the holiday’s history and importance.

Manufacturers! Hold your tools high, wear your grease stains with pride, and celebrate all your hard work, because today is National Manufacturing Day, and October is Manufacturing Month!

Didn’t realize that Manufacturing Day is a national holiday? It’s okay—it’s a relatively new holiday, as it was first declared on October 12, 2012. Only eleven years of celebrating an industry that has shaped America for hundreds!

The idea of Manufacturing Day was created back in 2011 in Rockford, Illinois, (but was officially recognized in 2012) as a way to break the industry’s stigma of hostile environments and labor-intensive work. The ultimate goal of the holiday is to shed light on how innovative and exciting manufacturing actually is, especially with the advanced technological skills and tools that have spurred the evolution of the industry, such as robots, computers, CNC machines, and more.

The manufacturing industry is one of the leading 10 industries in the United States, supplying 8.41% of the national workforce with jobs all over the country; that means roughly 12.5 million people work as or for manufacturers every year.

In 2021, 149,000 people worked for manufacturing companies in Colorado alone, making up 5.36% of the state’s workforce. Yet even though the industry is one of the tops in America, the growing shortage of trained workers has begun to affect the industry, leaving big gaps of unfilled positions.

These gaps then increase production time, lower company efficiency, and stunt industry advancement, which is why the breaking of stigmas and installment of internships and in-house training programs have become so crucial for recruiting the new generation of workers.

Here at James Engineering, we highly value learning opportunities and internship programs. Teaching the younger generation of manufacturing engineers about the industry advancements has been crucial for setting the stage for our future as a company, as well as their futures as individuals in the workforce. We provide our employees and interns with as much hands-on experience as possible, and we work together as a team to navigate the ever-changing world of manufacturing engineering. In Colorado, the top growing sect of the manufacturing industry is aerospace product and parts, which is what James Engineering, a Colorado-based company, has specialized in since being founded in 1980. We have become experts when it comes to aerospace part finishing, so much so that every plane in the sky has been touched by one of our machines. We know what it takes to succeed in the manufacturing industry, and we pass on our knowledge to those who are dedicated to further advancing our innovations.

Today it’s important to reflect on the impact the manufacturing industry has had on not only America, but the entirety of our world. The ever-developing industry has supplied millions of jobs to millions of people, and without these people, our planet would be a completely different place. Cars, airplanes, cellphones, medical equipment, even the clothes in your closet would cease to exist without manufacturing and all its astounding accomplishments. Here at James Engineering, we highly encourage those interested in the manufacturing industry to take any opportunity to learn more about its how’s and why’s, and to not be afraid to contribute their own original propositions. Manufacturing is no longer a dark-roomed, physically grueling industry that’s vicious on the body and mind—manufacturing is a technological, innovative industry nurtured by bright minds, inspiration, and passion.

For the rest of October, take a moment each day to observe the objects, equipment, and machinery around you that have been made possible by our world’s manufacturers. Take any chance you get to learn more about our mechanical surroundings, and push yourself to share your ideas with the world. You never know—you may be the next person to evolve the industry.

If you’d like to know more about the James Engineering impact, check out the rest of our website at https://www.james-engineering.com/. If you’re interested in joining our team, please send your resume or inquiries to Employment@James-Engineering.com, and we’ll get back to you as soon as possible!